Critical (Outdoor) IoT Applications Need Robust Connectivity

It’s safe to assume that the majority of all Internet of Things (IoT) devices operate near large populations of people. Of course, right? This is where the action happens – smart devices, smart cars, smart infrastructure, smart cities, etc. Plus, the cost of getting “internet-connected” in these areas is relatively low – public access to Wi-Fi is becoming widely available, cellular coverage is blanketed over cities, etc. But what about the devices out in the middle of nowhere? The industrial technology that integrates and communicates with heavy machinery that isn’t always “IP connected,” operating in locations not only hard to reach, but often exposed harsh weather. The fact remains, this is where IoT connectivity is potentially most challenging to enable, but also perhaps the most important to have. Why? Because these numerous assets help deliver the lifeblood for our critical infrastructures – electricity, water, energy, etc. Without these legacy and geographically dispersed machines, a smart world may never exist. But let’s back up for a second and squash any misconceptions about the “industrial” connectivity picture we’re painting above. Take this excerpt from Varun Nagaraj in a past O’Reilly Radar article: “… unlike most consumer IoT scenarios, which involve digital devices that already have IP support built in or that can be IP enabled easily, typical IIoT scenarios involve pre-IP legacy devices. And unfortunately, IP enablement isn’t free. Industrial device owners need a direct economic benefit to justify IP enabling their non-IP devices. Alternatively, they need a way to gain the benefits of IP without giving up their investments in their existing industrial devices — that is, without stranding these valuable industrial assets. Rather than seeing industrial device owners as barriers to progress, we should be looking for ways to help industrial devices become as connected as appropriate — for example, for improved peer-to-peer operation and to contribute their important small data to the larger big-data picture of the IoT.” It sounds like the opportunity ahead for the industrial IoT is to provide industrial devices and machines with an easy migration path to internet connectivity by creatively addressing its constraints (outdated protocols, legacy equipment, the need for both wired and wireless connections, etc.) and enabling new abilities for the organization. Let’s look at an example of how this industrial IoT transformation is happening. Voice, Video, Data & Sensors Imagine you are a technician from a power plant in an developing part of the world with lots of desert terrain. The company you work for provides power to an entire region of people, which is difficult considering the power plant location is in an extremely remote location facing constant sand blasts and extreme temperatures. The reliance your company places on the industrial devices being used to monitor and control all facets of the power plant itself is paramount. If they fail, the plant fails and your customers are without power. This is where reliable, outdoor IoT connectivity is a must: With a plethora of machinery and personnel onsite, you need a self-healing Wi-Fi mesh network over the entire power plant so that internet connections aren’t lost mid-operation. Because the traditional phone-line system doesn’t extend to the remote location of the power plant, and cell coverage is weak, the company requires Voice over IP (VoIP) communications. Also, because there’s no physical hardware involved, personnel never needs to worry about maintenance, repairs or upgrades. The company wants to ensure no malfeasance takes place onsite, especially due to the mission-critical nature of the power plant. Therefore, security camera control and video transport is required back to a central monitoring center. Power plants require cooling applications to ensure the integrity and safety of the power generation taking place. The company requires Supervisory Control and Data Acquisition (SCADA) networking for monitoring the quality of the inbound water being used to cool the equipment. The company wants to provide visibility to its customers in how much energy they are consuming. This requires Advanced Metering Infrastructure (AMI) backhaul networking to help manage the energy consumption taking place within the smart grid. Since the power plant is in a remote location, there is only one tiny village nearby being used by the families and workers at the power plant. The company wants to provide a

Drone Innovation: Supporting 2016 and Beyond

Drones are an interesting case study in the technology maturation process. Previously only available for military and defense applications, drone use have spread through the industrial and consumer markets faster than nearly anyone, especially the FAA, was prepared for. Despite the regulatory issues that have accompanied this growth, users are finding increasingly innovative and creative applications for the technology. This week, we’ve looked around for drone applications that really caught our eye for the potential long-term implications to the respective industries. Of course, for every example we’ve found, there are hundreds more. Let us know which applications you find most interesting! In case you need a recap, Donald Bell, with CNET highlights five industries that will be dramatically changed by drone use. Now that you are caught up on basics, check out the way drones are poised to save lives in remote areas of Malawi. The biggest problem with testing children in remote areas is the cost to get to the remote area and the time it takes to receive the tests back at a lab for testing. If Malawi is able to substitute drones for the courier service, they will save valuable time and be able to start treating. The Guardian reports that “Working with the government, Unicef is considering using drones to transport medical tests and blood samples from rural clinics to laboratories, avoiding the rutted roads that make even short journeys uncomfortable and unpredictable, partly because of fuel costs and a lack of motorbike drivers.” Drones can save lives, but can they also help us improve the experience on the links? Golf just got a whole lot more interesting in Japan! A new company has created a drone that with one click of your smart phone will bring you more golf balls or a refreshing beverage. What will drones do next? If your answer is, “finally make some of Batman’s crazy tools work in real life,” you would not be far off. Check out this footage from New Scientist of a drone mimic the flexible wings of a bat. Perhaps it’s simply a matter of time before we can strap on our utility belts and batwings and save the world… On the industrial side of things, drones are being used to gather data and infrastructure-related inspections, like bridges. The benefits for this project are twofold: drones could reduce the number of humans needed for the job, and they can also make the job safer by inspecting the more dangerous sections of the bridge. The Minnesota Department of Transportation has also tested the viability of drones for bridge inspections. It’s certainly a viable option that can translate across many industrial applications. Finally, what kind of society would we be if we didn’t begin to prepare our drones for the inevitable future of light sabers and hand-to-hand combat? All jokes aside, teaching drones to have this kind of reaction time to obstacles mid-flight could mean a step forward in some of the concerns about the use of drones in airspaces. For now, though, let’s appreciate this drone-turned-sword-evader. What else is out there? Let us know what you’ve seen around the world with drone applications!

Lifeguards Use Drones?

By Patrick Lazar, VP of Engineering at FreeWave Technologies Drones have actually been around for quite some time, even though the recent “lift-off” of commercial applications has vaulted the technology further into the spotlight. I’ve started seeing some incredible uses of the technology and how not only businesses will benefit, but people as well. For example, lifeguards and emergency responders have started flying drones as another means to quickly assist swimmers in trouble. By dropping a life jacket as soon as possible, distressed swimmers can get assistance quickly while further assistance is in pursuit of reaching the swimmer in the water. In the same vein, another reason lifeguards are flying drones is to identify and monitor other threats to beachgoers such as sharks. This will lead into drones enabling automatic warning systems when sharks get closer to the swim zones, and warn lifeguards to deploy means to both repel sharks and notify others in the surrounding area. My Take: Dropping life preservers are the most natural use case that comes into mind. However, once the use cases start being thought through with detection, prevention and lifesaving goals, a more intelligent system will be needed to sense events, deploy drones to assist, audible two way communication to help victims all the way through to safety, alert authorities to bring needed medical help to the closest recovery location and of course, warning other population nearby to prevent others falling victim to the same conditions. In all these cases, visual, audio, sensor info, command and control information must be sent back and forth to the drone, which will require reliable, long range communications. Furthermore, the payloads of these communication devices must be light/small enough to not affect the drones performance.

Robots Will Steal Your Future Paychecks

We’ve spent many words on this blog talking through new Industrial IoT technologies, hardware and software, and the way that the status quo has shifted to demand better connectivity, smarter infrastructure, and better access to real-time data across the spectrum. Where we haven’t spent much time is considering the economic impact these technologies will have on the average person. Without looking too far into the future, we can already see the impact of a more automated workforce. With that in mind, and on top of all our other daily worries, do we need to be worried about robots stealing our paychecks in the future? Eric Brynjolfsson, recently presented a TED Talk about this very topic, but unlike the sci-fi fear mongers, Eric had a different approach. Brynjolfsson suggests we stop trying to compete with machines and focus in on how they can complement our work-life. It’s true today it takes less people to get the job done. This shift to automation is forcing companies to rethink infrastructure and think more about speed, efficiency and overall time. This isn’t the time to reinvent the wheel, it’s time to think about how that wheel can be tweaked to operate more smoothly and consistently over time. Now, before you let your imagination run wild of a robot powered world, that will be lucky to be apart of, take a moment and watch Brynjolfsson’s TED Talk. Not to worry there is still hope, you may not have to hand over your paychecks to tomorrow’s robots, just yet!

Who’s Your Betamax of IoT Standards?

Image Courtesy of Flickr Creative Commons In the world of IoT/IIoT an explosion of standards has fallen upon us. While we all can agree that standards are what binds our current communication infrastructures together, it does take time for the victorious standard to rise to the top of adoption. Some of us remember the battle that arose in the video tape arena between VHS and Betamax (https://en.wikipedia.org/wiki/Videotape_format_war). While Betamax’s claim to fame was the superior picture, VHS had the longer recording time and a larger backing from the industry. In the end VHS won. And who can remember the tale of HD-DVD vs Blu-Ray, token-ring vs 10Base-T or WiMax vs LTE? Enter the IoT/IIoT wannabes. In the communication protocol arena we have standards such as 802.15.4 (ZigBee), 802.11ah (Wi-Fi HaLow) and LoRa that want to use the 900 MHz spectrum to connect your devices back to a gateway and then to your cloud. There are also application software framework standards such as Thread, Alljoyn, IoTivity, Arrowhead and LWM2M. I won’t even mention all of the cloud platforms that aim to bring all of these pieces together in one place. Really, how many people think about the actual physical mechanisms that enable connectivity throughout the world? And within that, who thinks about the standards set by organizations that dictate the best method for connecting all our devices? Standards have the potential to affect ranges of communication, battery life on remote devices, signal interference, and many other things. The interesting part about the race to the top, so to speak, is that the standards mentioned above all have viable aspects that could potentially make them the ideal solution for connected infrastructure. Many of these standards have consortiums with major players such as Google, Microsoft, ARM and Samsung, all of which play at different places in the IoT/IIoT theatre. So, unlike the tail of Betamax, many of these standards have the backing of multiple entities. But, who’s going to win? Which standard will come out on top? Or, will we find ourselves with multiple standards because we can’t agree on one to do the job? What do you think? Who is your Betamax pick for IoT/IIoT?

Video: What are the Future Uses of Drones?

While drones are responsible for one of the latest tech crazes to hit the mainstream, it’s safe to say that you should not expect them to invade your airspace anytime soon. However, the influx of these flying smart machines may not be as far off as you might think. With heavy-hitters like Amazon, Google and Walmart recognizing the immense opportunity of using drones for shipping and logistics purposes, its no wonder that people are saying “the drones are coming!” Industrial Applications for Drones What could prove to be more promising than the consumer-driven demand for flying drones is the use of that technology in industrial settings and applications. Already, we see companies using drones for the following scenarios: Emergency Response Enables immediate action, providing emergency response teams with fast, flexible visibility to assess critical situations. Utilities Safely allows for the quick inspection of high voltage power lines and wind turbines, helping mitigate worker risk and improve monitoring. Military & Defense Assisting with intelligent surveillance and reconnaissance missions to deliver timely, relevant, and assured information to thwart potential threats. Oil & Gas Protects and helps maintain extensive miles of pipeline covering large, remote areas that would otherwise require enormous amounts of time and resources. Agriculture Creates more efficient farms by monitoring inventory, growth, water and fertilizer levels, and crop health to facilitate production and increase yields. Public Safety Supporting firefighting operations by providing more up-to-date information at a lower cost, while reducing the number of responders in harm’s way. So what does the future hold for these next-generation technologies? It’s hard to say really. One of the biggest hurdles still to jump is figuring out how these aircrafts will fit into the Federal Aviation Administration’s (FAA) existing airspace regulations. There is no doubt there will be new policies that are drone-specific on the horizon. In fact, the FAA has already taken steps in that direction by requiring drone owners to register their aircrafts as a first step in ensuring the safety of everyone who uses the skies. Let’s just assume that over then next five years policy and technology come together and we finally have lift-off in the drone world. What’s next? Check out this video courtesy of Be Amazed that explores 10 amazing futuristic uses of drones:

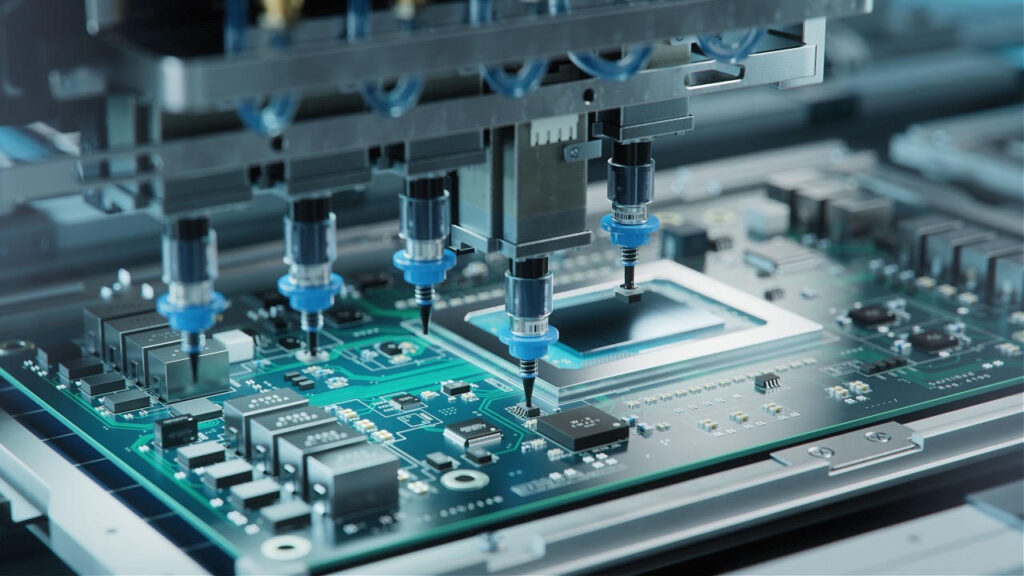

Top News: Manufacturing the Fate of Our Digital World

Manufacturing is in the midst reinventing itself on the heels of the latest IoT innovations. The industrial automation paradigm, which some say also gave rise to the lean manufacturing management philosophy, continues to influence organizations that wish to find new ways to capitalize on business opportunities in the digital age. Through that lens we gathered the top articles from the week and found some interesting perspectives. Some reports started suggesting manufacturing is in a time of trouble, both in the U.S. and around the globe, namely in places like China. But upon further investigation, we also find exciting trends that are shaping the evolution of manufacturing. We hope you enjoy this week’s roundup, and be sure to comment on your top articles of the week below! Chinese manufacturing fall adds to evidence of sharp global downturn (The Guardian) As the world watches Chinese manufacturing slow, many believe this is evidence of a major global downturn. The Guardian reminds us all that, “In another sign that manufacturers are braced for a long period of chasing business from a diminishing number of customers, they continued to lower their prices in February.” American Manufacturing in Peril (U.S. News) Gone are the golden days of domestic manufacturing, analysts now believe American manufacturing is in serious trouble. Andrew Soergel with U.S. News suggests that part of the problem for manufacturing is that, “The job market has changed. The generation has changed. The skill requirements to work in factories have changed.” The Manufacturing Side of CPG’s Digital Disruption (Automation World) In this era of digital disruption, consumer buying behavior will impact manufacturing practices. According to Stephanie Neil with Automation World, she thinks manufacturing could benefit from, “The use of standardized, reusable software modules simplifies configuration of robotic movements and integration with machine control functions. This allows machine builders to focus on increasing machine performance, added functionality, and equipment energy efficiency.” Despite all this talk about downturn and disruption in the manufacturing industry, there are some positive trends we should mention as well. Top 10: Manufacturing Trends of 2015 (Manufacturing Global) IoT, nanotechnology, SMAC Stack and greater visibility were all key manufacturing trends last year. According to Manufacturing Global’s trends, “Additive manufacturing, or 3d printing, is big news in the manufacturing sector. The new technology has captured the imagination of the general public and manufacturing executives alike, however it has also proven to be a game-changer for the industry.” 3-D Printing Poised to Shake up US Manufacturing (New York Post) In the last year 3-D printing has shown up in the medicine cabinet, operating rooms and even New York Fashion week. U.S. Manufacturing is getting a serious shake up with the launch of more 3-D printers. Catherine Curan with New York Post states that, “The 3-D printing boom isn’t big enough to single-handedly revive local manufacturing, but it will help.”

Top News: IoT Rules at Mobile World Congress (MWC)

After a week of everything mobile, at least in Barcelona at the Mobile World Congress (MWC), it is only fitting this week’s top news recap focuses on the other three letter acronym so hotly discussed from the show – IoT. Whether you have been living under a rock or just hadn’t embraced the fascination with the latest handheld smart technologies and cellular networking, this week’s Mobile World Congress (MWC) presented by GSMA, brought together around 800 mobile operators from more than 250 companies from around the globe to discuss the latest products, software and innovations that will push the IoT space even further into maturity. Some of the key themes to come out of this year’s MWC were the fifth generation wireless systems or 5G, the impact this next-gen tech and mobile will have on the Internet of Things (IoT) and the booming IoT businesses laying the foundations of the connected world. Now as you nestle up to your favorite mobile device or smart tablet, relax and dive into this week’s IoT news roundup from MWC! MWC: 5G Key to unlocking IoT … Just Not Yet (IndustryWeek) As the MWC surged forward with excitement for 5G to finally unlock IoT, experts warn the connective battle isn’t over, as the world dives into incorporating 5G throughout. Agence France-Presse with Industry Week reports that, “5G is the term on everyone’s lips at the Mobile World Congress in Barcelona and a global race to develop it is under way.” IoT Race Heats up at MWC 2016 (RCR Wireless) The race heats up for IoT, as 2G networks scramble to find a new way to connect with the announcement of 5G at MWC 2016. “Mobile World Congress is all about the newest wireless technologies, but this year the end of an old technology is driving conversations around the Internet of Things.” This Week’s 5G Buzz Indicates IoT is Finally Kick-Starting (VentureBeat) The hot topic on everyone’s mind this week had to be 5G and the need for more IoT connectivity. Leon Hounshell, with Greenwave Systems reminds us that, “Regardless of the hype, CES and MWC do not reveal an IoT revolution, but they certainly show us a determined evolution, where devices will unceasingly become more connected, open, and smart.” Mobile World Congress: Internet of Things Business is Humming (USA TODAY) This week may have shown us a lot of shiny new IoT products for consumers, but the truth is IoT for business will really dominate deal-making. USA TODAY believes that, “It’s not hard to see why. Gartner forecasts that the market for IoT services will top $101 billion this year, nearly 30% more than the $78 billion that businesses spent last year. By 2020, spending for services like network deployment, operations management and data analytics is forecasted to balloon to $257 billion.” Mobile World Congress: Why Every Brand Should Become a Tech Brand (Campaign Live) Connectivity is everything, and moving forward in this technological age the MWC believes all companies should become a tech brand in order to incorporate IoT. Natalie Bell with Campaign Live states that, “We are now in an era of connecting everyone and everything. So, while Mark Zuckerberg is urging us to focus on the former and ensure wider basic connectivity across the entire globe, there’s a huge tech focus on the latter — the Internet of Things, which will be greater enabled by the increasing capacity in 5G. It’s this vast array of connected objects that have caught my attention this year.”

DistribuTECH 2016 Day 1 Recap: People, Places and Things

Each year, we attend a wide variety of trade shows for many different vertical industries. These shows present several opportunities: we get to go talk about ourselves a little bit, we get to see what other companies and thought leaders are doing, and we get to talk with some very interesting folks who have varying perspectives on the industry, the trends and the technologies that drive growth. This year, at DistribuTECH 2016 in Orlando, Fla., we wanted to jot down some brief, daily thoughts on some of the things that we saw both around our booth and at the show in general. Record number of attendees! We were pretty excited to hear that there were a record number of attendees at this year’s show. It’s an exciting time to be a part of the utilities and energy industries. Lots of changes, some really great and innovative new technology, and a bevy of thoughtful people makes for a good trade show! Wearables?! Where are we, CES? No! Wearables are not just for the consumer-driven recreational technology market. Wearable technology has the chance to change the way our boots on the ground and in the field work. The adage about working ‘smarter, not harder’ certainly applies to some of the companies developing wearable technology for the industrial sector. Great speakers abound! With a huge portion of the journalism industry in shambles, publications like PowerGrid International (one of several from PennWell) really stand out for its consistently solid and informative material. It’s always great to see the ‘Ink-Stained Wretches’ get their due, and Teresa Hansen, editor in chief of PowerGrid International and Electric Light & Power, gave an excellent keynote on the first day. Hey, look at us! It’s always a little uncomfortable talking about yourself, but we are incredibly excited about the future at FreeWave, and many of the people we talked with who came through our booth – attendees, media, analysts, customers, etc. – were excited as well, namely about our new WavePro WP201 wireless shorthaul Wi-Fi solution. There are some features that we’re especially proud of, including the high-speed Voice, Video, Data and Sensor Data (VVDS) transmission capabilities, the self-healing one-mile industrial Wi-Fi hotspot and the ability to achieve maximum throughput. We’re excited for day 2 – keep an eye out for us!

Solving The Challenges of Remote Wi-Fi in the Industrial Internet of Things

Most of us can relate to the frustration of when the Wi-Fi is down, or running slowly, or if we travel away from an established network and aren’t able to connect to another one nearby. The lack of Wi-Fi makes it impossible to check our emails, look up something on the internet, connect with others, or get our work done efficiently. In short, it makes us feel a little helpless and a whole lot of cranky because we’ve become way too accustomed to getting the information we want – when we want it – and staying in 24/7 connection with our world. Now, if we’re challenged by our Wi-Fi experiencing a service blip in a metropolitan area, imagine a remote industrial setting like an oil pad, a water treatment plant, or a rural electric tower. All of these reside in what is known as the access layer – or at the very outer edge of an IT network. Not only is there usually no internet connectivity in the access layer, but these devices are typically operating in rugged terrain where they’re experiencing extreme and volatile weather conditions such as wind, snow, blistering heat, tornadoes, dust storms, etc. Each of these access layer settings is part of a larger industrial Internet of Things (IIoT) network that connects the information gathered from local sensors that transmit or receive operational data. From there, they pass it along through subsequent network touch points all the way to the IT department at headquarters where this data is collected, analyzed, and acted upon for improved decision making. So, at the access layer – sometimes in the middle of nowhere where there can be no Wi-Fi networks for miles – talk about being disconnected from the world! Adding the environmental component to that, as well as the fact that most of these remote sites aren’t adequately monitored and data security is at risk, it makes your occasional Wi-Fi challenges seem a bit tame, yes? Here’s where wireless IIoT communications technology can help transmit this critical sensor data from remote industrial locations with no Wi-Fi connectivity all the way to where they’re supposed to go – and at very high speeds. This week, FreeWave is launching its new WavePro™ WP201 shorthaul and Wi-Fi platform that delivers secure collection, control, and transport of Voice, Video, Data, and Sensor (VVDS™) information from the access layer. Think of it as high-speed, rugged Wi-Fi connectivity that can be positioned in that oil pad, power plant or wherever Wi-Fi is needed. It will not only connect these sensors to the internet, but can also transport voice and video to create an instant in-field network, provide greater visibility into what’s going on at these sites, and better protect remote assets. The Advent of Short Haul and the Access Layer Change is inevitable, and change is taking place in SCADA, M2M and IIoT networks. SCADA networks started as networks that transported periodic process updates and used low bandwidth networks with longer links to meet their mission. Today, remote SCADA and Wi-Fi networks are transporting more data from more sensor data with greater frequency in order to drive operational efficiency into business processes. SCADA and M2M networks are becoming more multi-functional than their predecessors. These networks are transporting more than sensor data from the remote site to the enterprise. These networks linking remote sites to the enterprise network are now transporting: Video for remote process monitoring, enhanced site security and theft deterrence Voice, since cellular coverage is not ubiquitous Data so field personal have access to information needed to work efficiently This combination of data types is what FreeWave terms as VVDS™ (voice, video, data and sensor). VVDS transport is now a requirement for your wireless network. Another change occurring in traditional SCADA networks is that link distances are decreasing. In the past, SCADA networks with wireless links of more than 10 miles were common. Today, wireless links in excess of 10 miles typically use high speed, microwave, point-to-point (PTP) systems because of the increased capacity demands of VVDS. The WP201 links the formerly unconnectable and is designed to not only meet the harshest environmental conditions, but also encrypts the data to keep it secure and protected. It can be used in a wide variety of industries like oil & gas, utilities, mining, disaster recovery, facility automation – anywhere where field sensor information needs to be transmitted to servers for Sensor-2-Server™ (S2S™) connectivity. The applications are almost limitless. With higher speed, shorter wireless links, FreeWave defines wireless networks in three tiers: Long Haul (or the Distribution Layer) are wireless links from 5 miles, and greater and are typically implemented using high speed, PTP microwave systems. Short Haul (or the Aggregation Layer) are wireless links from 1 to 8 miles that are easily implemented using high speed, 2.4GHz or 5GHz radios with directional antennas to create point-to-multipoint (PMP) networks for data and information aggregation, or PTP links that provide network ingress/egress points. Close Haul (or the Access Layer) are PMP networks with wireless links operating from a few feet to a couple of miles to transport VVDS data. Designing and deploying wireless networks using a layer approach that enables each layer to be optimized for transport and for cost ─ leveraging the right equipment at the right point. The WP201 and its remote Wi-Fi and short haul capabilities is the first in a series of S2S products that FreeWave is offering to be that critical communication bridge in the IIoT world. So in your own operations, what are some ways you might incorporate the WP201 into your network?